Resharpening Services

- As manufactures of premium cutting tools, we understand how important proper tool geometry is. Sharp Cutter Grinding takes pride in our CNC Regrinds.

- Our customers can rest assured that their High Performance Drills, Ball Noses and High Feed end mills will cut like new.

- Coating available.

- Sharpening is performed on CNC machines.

- Fast turn around times keeps manufacturing costs down.

- Capable of resharpening all brands.

- When sending in your resharps, please print and fill out our Resharpening Send In Sheet

Before

After

- Center Drills

- Taps

- Roughers

- Gun drills

- Counter Sinks

- Chaterless Counter Sinks

- Back Spot Facers

- T-Slots

- Spade Drills

- Turbos

- Side Mills

- Love Joys

- Dove Tails

- End Mills

- Drills

- Reamers

- Variable Flute

- Spotting Drills

- Engravers

- Finishers

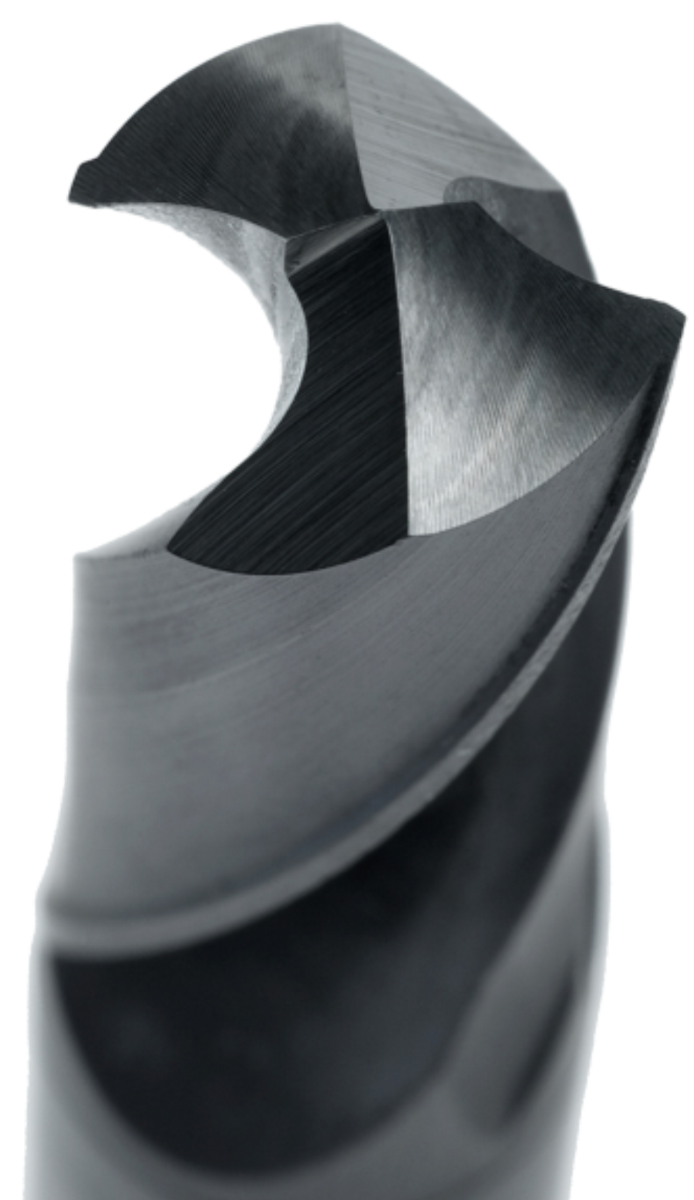

High Performance Carbide Drill Resharpening

- Facet or Conical points.

- Sharpening is performed on CNC machines.

- Fast turn around times keeps manufacturing costs down.

- Capable of resharpening all brands.

- Quality inspection procedures.

- Coating available.

- H.S.S. Drills are also able to be resharpened, please call for a quote.

- No minimum required.

We have been sending our drills to Sharp Cutter Grinding to have them resharpened for years. They always cut on size and we can count on a very consistent number of holes per drill on our production runs. I love the fact that I am able to send all my different brands of drills to Sharp Cutter Grinding for resharpening.

- Steve, Auburn Hills MI